Choosing the right SSD could save you more than just your data

There’s a saying that goes ‘buy cheap, buy twice’, the meaning of which is fairly clear; if you choose a cheaper and inferior product, you will probably need to replace it sooner than you’d hoped. I’m sure the same sentiment can be found in other proverbs in other languages and cultures, because it is an undeniable fact that quality costs.

When the quality is apparent and can be easily examined, the decision process should be fairly simple. Some will, of course, still hope for the best from something they probably know is actually poorly made or not suitable for the job, but what happens when quality is effectively implicit? When buying a product from a trusted supplier, is it unreasonable for the buyer to expect it to meet their expectations, particularly if it is marketed under those same expectations?

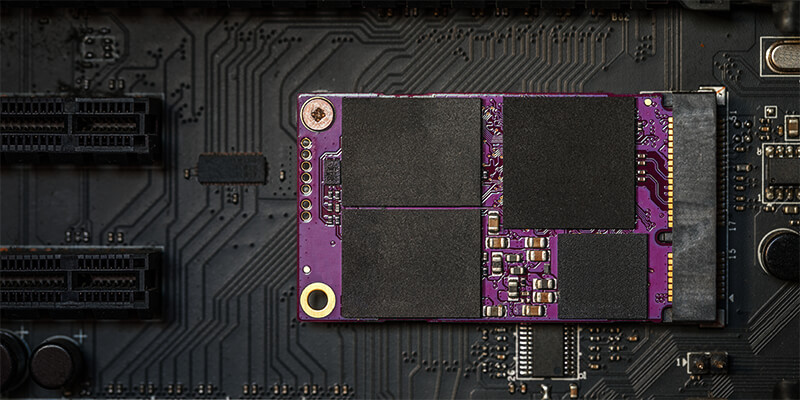

The confusion creeps in when choosing between two products that appear to offer comparable quality but for vastly different prices. The temptation is always to choose the cheaper option, even if we accept the limitations this might impose. As an example, consider the difference between two embedded NAND based Flash memory systems; one designed for consumer applications and one that is intended to be used in an industrial environment.

Ostensibly they may appear the same, they may not even be that differently priced, but there will be significant differences in their performance, reliability and longevity.

The demands on an SSD

Industrial applications, in general, demand more from electronic components; it’s why they are certified to operate across an extended temperature range. The move towards Commercial Off The Shelf, or COTS, in military and aerospace applications may imply that it’s ok to use commercial grade components in ‘hi-re’ applications but in reality anything that is COTS still gets qualified for use in that environment, it isn’t simply an off-the-shelf product.

The use of NAND Flash solid-state storage (SSD) in industrial applications is a case in point here. Thanks to their common interface, it is possible to use consumer-grade storage in any application, including industrial, but in reality this will not meet the very specific demands of the industrial sector.

One of the most apparent features of consumer technology is a short lifespan, a direct result of cheaper components. Manufacturers tend to revise their product offering frequently in order to take advantage of the latest developments in speed and density. For an industrial application continuity of supply is important, it may take many months to fully qualify a product for use in an industrial application, so they are looking for long-term availability with a controlled Bill of Materials (BoM). This, too, is not the case with a consumer device, as the manufacturer will very likely design-out one component in favor of another if it is slightly cheaper or has a shorter lead time; rarely will the substitute device behave in exactly the same way as the original.

From a performance point of view, consumer SSDs are built to a price, so the performance may vary based on the BoM for that particular build. Again, in an industrial environment this is intolerable, as the storage solution may form part of a mission critical system that may have very rigid latency requirements in a real-time environment.

Another key concern in a connected age is security. Adding security can often impose greater demands on the processing elements, which could impact performance. Avoiding the overhead of security could increase overall performance, but at what cost? In an industrial application, performance is important but security is likely to be of high value.

The durability of the NAND Flash is also an issue. Features such as wear levelling avoid errors and ensures that the NAND Flash is managed efficiently and its endurance is maximum. An industrial application is likely to exhibit very different use-cases to a commercial SSD, so the program/erase cycles will differ massively. A consumer device may need to deliver 1000 cycles, while an industrial SSD could be expected to achieve 100 times that number.

SSDs designed for an industrial environment will provide features specifically intended to mitigate the impact of a fault condition, such as sudden power loss. Most SSDs will provide some level of protection here, but you can expect an SSD designed for an industrial application to provide greater protection than you will find in a consumer device.

The Flash Controller

Another form of data protection comes from Error Correction Code, or ECC. This has developed into one of the most complex aspects of Flash management, one that is handled by the Flash Controller. The functions involved with ECC to repair errors are mathematically complex; each Flash vendor allocates space for storing parity data based on their ECC requirements. This in turn guarantees the devices endurance. The ECC algorithm can be optimized for latency and quality, and is for soft decoding dependent on probabilities. The quality of the correction offered is often quoted in terms of the Uncorrectable Block Error Rate (UBLER) based on the Flash device’s own Bit Error Rate (BER).

Because the Flash controller is so influential on the overall quality of the SSD, some manufacturers prefer to match a Controller to the Flash used, in order to help guarantee quality. All of the Flash devices supported by Hyperstone’s Flash Controller have been rigorously tested in order to be able to provide this level of assurance.

Solid-state drives are ubiquitous to the point of being commoditized but that doesn’t mean all are created equal. The key point here is that, for an industrial application, specifying an industrialized SSD is the right choice. Ultimately it will deliver a lower Total Cost of Ownership (TCO), even if the initial cost is higher. The most important question to ask is, shouldn’t the value of your data be measured in terms of reliability and safety?